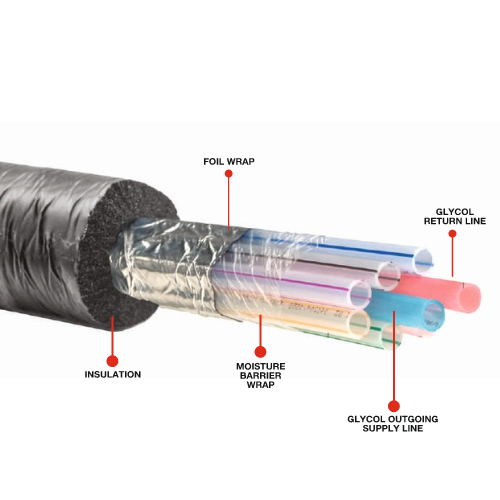

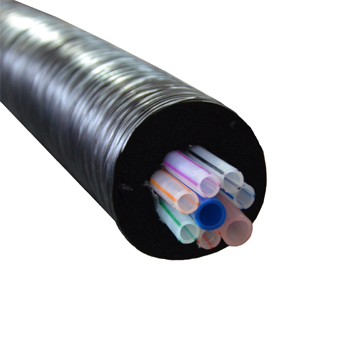

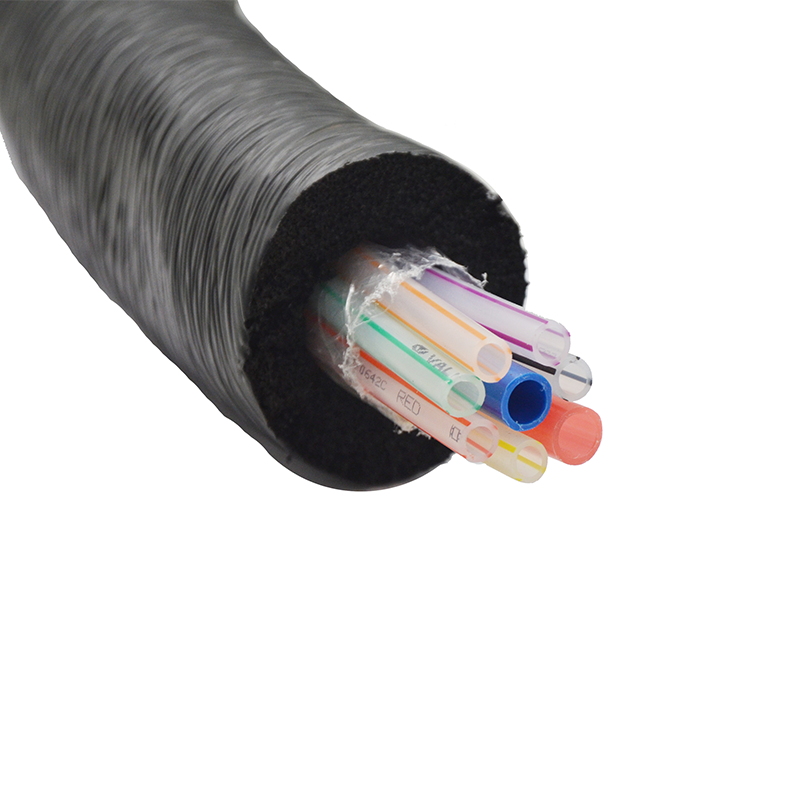

Beverage tubing glycol trunk line

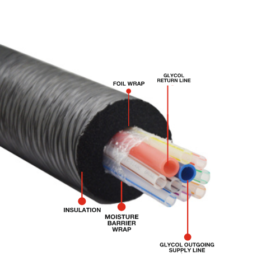

A beverage tubing glycol trunk line is a specialized system used in draft beer or beverage dispensing setups, particularly in commercial settings such as bars, restaurants, or breweries. It’s designed to efficiently transport beverages, typically beer, from the keg room to the tap towers where the beverages are dispensed.

Other Options Available:-

| Part No. | C2264 | C2267 |

| Number of lines | 6 | 8 |

| Diameter | 23/8″ | 23/8″ |

| Moisture barrier wrap | Food Quality Barrier Film | Food Quality Barrier Film |

| Barrier jacket | Smooth Vinyl | Smooth Vinyl |

| Insulation | 3/4″ (19mm) closed cell | 3/4″ (19mm) closed cell |

- Number of Lines: The assembly consists of six individual lines or tubes. This suggests that it can accommodate multiple channels or conduits for different purposes, such as transporting different beverages or fluids simultaneously.

- Diameter: The diameter of each line is 2⅜ inches (approximately 60.325 mm). This diameter indicates the size of the tubes, which may be suitable for carrying a significant volume of liquid or gas.

- Moisture Barrier Wrap: The tubing is wrapped in a food-quality film, acting as a moisture barrier. This feature ensures that the contents of the tubes remain protected from external moisture or contaminants, maintaining the quality and integrity of the transported substances.

- Barrier Jacket: The assembly includes a smooth vinyl barrier jacket. This jacket provides additional protection and durability to the tubing, shielding it from damage and ensuring long-lasting performance.

- Insulation: Each line is insulated with 3/4 inch (19 mm) closed-cell insulation. This insulation helps regulate the temperature of the contents within the tubes, preventing heat transfer or loss and maintaining the desired temperature conditions.